Product Description

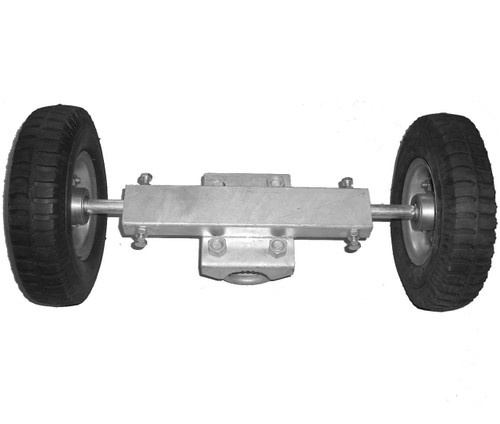

Industrial Chain Link Double Wheel Carriers — Galvanized, 6″ or 8″ Solid Wheels (Bolt-On or Weld-On)

- Built for Heavy Service — Industrial-duty carrier supports the leading edge of rolling chain link gates

- Fits Common Framework — Adjustable U-bolts for 1-5/8″ or 1-7/8″ O.D. gate frames

- Smooth Travel on Hard Surfaces — Solid wheels excel on concrete and asphalt approaches

- Bolt or Weld — Clamp on in minutes, then weld if you want maximum rigidity

- Corrosion-Resistant — Galvanized steel frame for long outdoor life

Keep wide openings moving reliably with a rugged double wheel carrier engineered for commercial and industrial rolling gates. This assembly mounts at the gate’s leading edge to bear weight and keep the leaf gliding true. Solid wheels are ideal for flat, hard paths (driveways, yards, plant entrances), and the galvanized frame stands up to weather. Choose 6″ or 8″ wheels to match your surface, slope, and clearance requirements—an efficient, professional grade alternative to more complex track or cantilever systems when the surface is suitable.

Why Choose This

- Pro performance — Heavy steel carrier with solid wheels for daily use on busy gates

- Easy fit — U-bolt mount adapts to 1-5/8″ or 1-7/8″ O.D. frameworks; weldable for permanence

- Dialed-in operation — Height/angle adjustment helps the wheels share the load and track straight

- Weather tough — Zinc galvanization resists rust and corrosion outdoors

Specifications

| Industrial Carrier Wheel Size | 6" | 8" |

| Actual Gate Framework Size (O.D.) | 1-5/8" or 1-7/8" | 1-5/8" or 1-7/8" |

| Wheel Type | Solid | Solid |

| Weight | 8 lbs | 11 lbs |

| Material | Galvanized Steel | Galvanized Steel |

| Finish | Silver | Silver |

| Typical Usage | Commercial & Industrial Chain Link Rolling Gates | Commercial & Industrial Chain Link Rolling Gates |

Installation

Mount the carrier to the front (leading) edge of the gate’s bottom framework with the included U-bolts. Set height so both wheels share the load and roll freely on a hard, smooth path (concrete/asphalt). Tighten hardware and test travel. For maximum rigidity, stitch-weld the carrier to the frame after alignment (optional). Re-check fasteners after initial cycles.

Buying Guide

- Wheel size: Use 6″ for level, smooth approaches; 8″ adds clearance over joints, transitions, and mild grade changes.

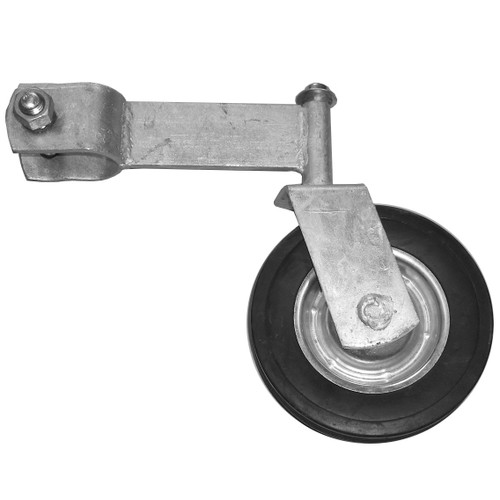

- Surface type: Solid wheels are best on concrete/asphalt. For gravel or uneven ground, consider a pneumatic “rut-runner” style carrier.

- Gate layout: One double wheel carrier typically supports the leading edge; the rear rides on pipe track and rear wheels.

- Fitment: Confirm your framework O.D. (1-5/8″ or 1-7/8″). Tighten clamps evenly; verify wheel alignment before optional welding.

Frequently Asked Questions

- Does it include mounting hardware?

- Yes. U-bolts and nuts sized for 1-5/8″ or 1-7/8″ O.D. gate frameworks are included.

- How many carriers does a gate need?

- Typically one double wheel carrier at the leading edge of a single rolling gate. The rear of the gate rides on pipe track with rear wheels.

- Will this work on gravel or uneven ground?

- Solid wheels are intended for hard, smooth surfaces. For rough or irregular approaches, a pneumatic double wheel carrier is recommended.

- Can I weld it instead of bolting?

- Yes. It bolts on for easy setup and can be welded to the frame after alignment for a more permanent, rigid installation.

- What size frames does it fit?

- It fits 1-5/8″ and 1-7/8″ (2″ nominal) round gate frameworks.

Comparison

- Industrial Double Wheel Carrier (this item): Solid wheels for concrete/asphalt; quick bolt-on; weldable; ideal for heavy daily use.

- Pneumatic “Rut-Runner” Carrier: Air-filled tires for rough or uneven surfaces; better over gravel but requires tire upkeep.

- Residential Double Wheel Carrier: Similar function for lighter gates; this industrial model uses heavier components for tougher duty.

Product Videos

Custom Field

Product Reviews

1 Review Hide Reviews Show Reviews

-

worked great

having never done this before, my son helped by ordering from your company and we were able to install ourselves!